-

Industries OverviewThe company's products are primarily used in industrial equipment sectors such as nuclear power, petroleum, petrochemicals, chemical engineering, power generation, automotive manufacturing, shipbuilding, fertilizer production, pharmaceuticals, papermaking, sugar refining, and machinery manufacturing.

Industries OverviewThe company's products are primarily used in industrial equipment sectors such as nuclear power, petroleum, petrochemicals, chemical engineering, power generation, automotive manufacturing, shipbuilding, fertilizer production, pharmaceuticals, papermaking, sugar refining, and machinery manufacturing. -

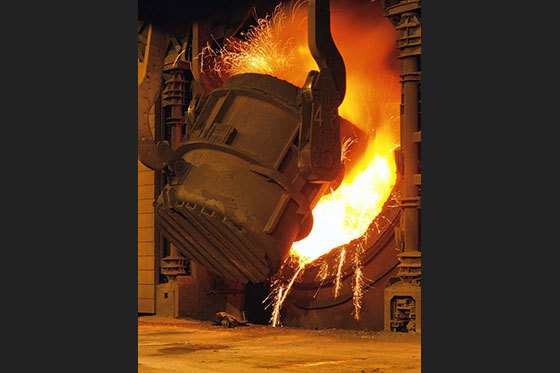

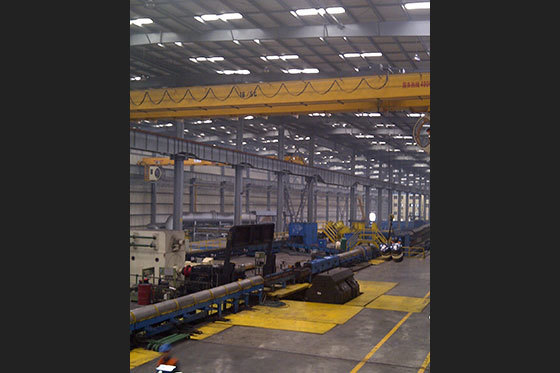

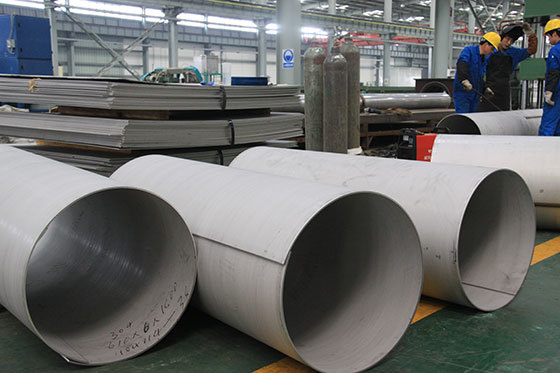

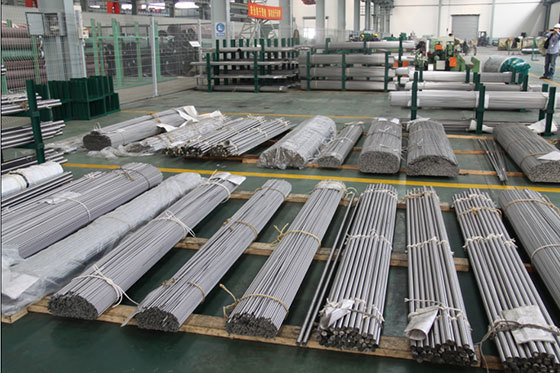

Products & SolutionsOur Products: Ferrous metal ore raw materials (nickel ore, ferronickel, ferrochrome, ferromanganese, ferrosilicon, etc.), seamless pipes, welded pipes, medium-thick plates, plate coils, bars, wire rods, wire coils, pipe fittings, flanges, castings, etc.

Products & SolutionsOur Products: Ferrous metal ore raw materials (nickel ore, ferronickel, ferrochrome, ferromanganese, ferrosilicon, etc.), seamless pipes, welded pipes, medium-thick plates, plate coils, bars, wire rods, wire coils, pipe fittings, flanges, castings, etc. -

CommunityThe company has established an excellent reputation within the industry through its strong credibility, comprehensive services, and ample resources.

CommunityThe company has established an excellent reputation within the industry through its strong credibility, comprehensive services, and ample resources. -

Process VisualizationThe company's products are primarily used in industrial equipment sectors such as nuclear power, petroleum, petrochemicals, chemical engineering, power generation, automotive, shipbuilding, fertilizer production, pharmaceuticals, papermaking, sugar refining, and machinery manufacturing.

Process VisualizationThe company's products are primarily used in industrial equipment sectors such as nuclear power, petroleum, petrochemicals, chemical engineering, power generation, automotive, shipbuilding, fertilizer production, pharmaceuticals, papermaking, sugar refining, and machinery manufacturing. -

About UsTsisco Industrial Ltd. was established in 2010. Originating from the Tsingshan ecosystem’s Shanghai platform, the company now operates independently and focuses on global supply-chain integration, distribution, and import/export of steel and alloy materials. We achieved ISO 9001 certification from TÜV Rheinland in 2012, and ISO 9001, ISO 14001 and ISO 45001 certifications from LRQA in 2022. These accreditations underpin continuous improvement and stable performance in quality, environment, and occupational health & safety.

About UsTsisco Industrial Ltd. was established in 2010. Originating from the Tsingshan ecosystem’s Shanghai platform, the company now operates independently and focuses on global supply-chain integration, distribution, and import/export of steel and alloy materials. We achieved ISO 9001 certification from TÜV Rheinland in 2012, and ISO 9001, ISO 14001 and ISO 45001 certifications from LRQA in 2022. These accreditations underpin continuous improvement and stable performance in quality, environment, and occupational health & safety.

-

Process Visualization

Visit Us

Technical Plant Tour (Equipment · Functions · Process · QA/QC · Product Mapping

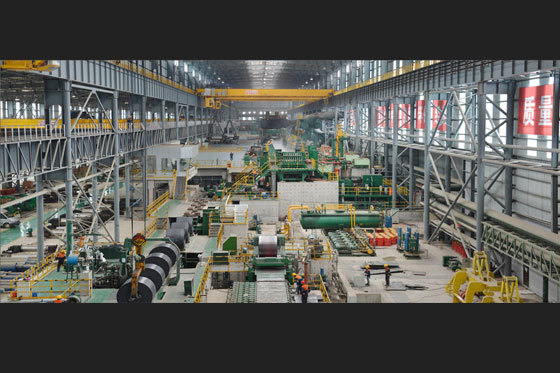

Main Route: Raw Materials → Ironmaking → Steelmaking & Secondary Metallurgy → Continuous Casting → Hot Rolling → Cold Processing & Finishing → Surface Engineering & Corrosion Protection → Quality & Certification → Packing & Shipment

NEW Stainless Branch: Laterite Nickel Ore → RKEF (Rotary Kiln–Electric Furnace) Ferronickel (NPI) → Hot-charged AOD (+ Ferrochrome) → Refining (VOD/VD as needed) → LF → Casting → same downstream as main line.

0. Entry & Overall Flow

• Equipment: Gantry cranes, stacker-reclaimers, enclosed conveyors, on-line sampling & lab, utilities (steam/GOX/GN₂/GAr/natural gas, gas holders).

• Function: Receiving, classification, automated batching; utilities scheduling with interlocks.

• Process: “Ore–Coke–Flux–Scrap/Alloys–Energy” closed loop from receiving to batching.

• QA/QC: Chemistry (OES/ICP), size & moisture, sinter strength, coke CRI/CSR; batch retention policy.

• Product mapping: Sets baseline for cleanliness & weldability and MTC (EN 10204 3.1/3.2) traceability.

1. Raw Materials & Preparation

• Equipment: Stockyards, blending stations, sinter plant or pellet shaft kiln/rotary kiln, CDQ, lime kiln, annular cooler, dedusting & DeSOx/DeNOx.

• Function: Blending, agglomeration, coking, lime calcination.

• Process:

• Iron ores: Zoning by TFe/SiO₂/Al₂O₃/P/S, PSD, return fines ratio; produce stable sinter/pellets.

• Coking: Coal blending → coking → CDQ heat recovery; by-products utilization.

• Fluxes: Control basicity, size and lime activity.

• For stainless: Laterite nickel ore drying & pre-reduction prior to RKEF; control moisture, Ni grade and gangue.

• QA/QC: Sieve analysis, tumble & hot/cold strength, continuous emissions monitor.

• Product mapping: Stable burden for BF/EAF and feed for the RKEF-AOD route.

2. Ironmaking (BF or Direct Reduction)

• Equipment: BF, bell-less top, hot blast stoves, PCI, cast house; or DRI shaft/HBI unit.

• Function: Produce hot metal or DRI as metallic feed.

• Process: BF with O₂ enrichment & PCI; DRI/HBI with NG/H₂ reducing gas.

• QA/QC: Hot metal chemistry & temperature, slag basicity; TRT & gas safety interlocks.

• Product mapping: Carbon/low-alloy feed; EAF+DRI route for stainless is optional.

3A. Steelmaking & Secondary Metallurgy (Main)

• Equipment: BOF, EAF, LF, VD/RH/VOD, argon stirring, on-line sampling/pyrometry.

• Function: Decarburization/dephosphorization/desulfurization, alloying, inclusion control, degassing.

• Process: BOF top-bottom blowing; EAF foamy-slag melting; LF trimming and inclusion modification; VD/RH for H/N/O removal.

• QA/QC: Spectrometry, H/N, inclusion rating (ASTM E45/ISO 4967), temperature hit rate; fume/noise/EM protection.

• Product mapping: Carbon, low-alloy, structural, pressure vessel, ship/bridge plates.

3B. Stainless NPI-AOD Branch (NEW)

• Route: Laterite Ni ore → RKEF ferronickel (NPI) → hot-charged AOD (+ FeCr) → VOD/VD (as needed) → LF → Casting → downstream same as main line.

• Equipment: Rotary kiln & electric furnace (RKEF) or rotary furnace + EAF; NPI launder & insulated ladle; AOD converter with O₂-Ar (or O₂-N₂) blowing; alloy addition (FeCr etc.); vacuum station; LF.

• Functions:

1. RKEF: Pre-reduction and smelting to NPI; control Ni/Fe/Si/S/P and tapping temperature.

2. AOD: Deep decarburization with minimal Cr loss via O₂-Ar ratio & lance control; FeCr addition to target Cr window; nitrogen control for austenitic/duplex grades.

3. Refining + LF: VOD/VD for degassing (H/N/O); LF for homogenization and inclusion modification to hit final composition.

• Key controls: O₂/Ar ratio & lance position; AOD slag (CaO-SiO₂-MgO) and [Cr]–[C] equilibrium; N control by N₂ participation or late alloying; Al/Si deoxidation and Ca treatment.

• QA/QC: NPI chemistry; AOD pre/post spectrometry, O/N/H; inclusion rating (ISO 4967); A923 (duplex), G48 pitting, A262 IGC where applicable; process curves (gas flows, time, slag, temperature).

• Product mapping: Austenitic (304/316/321/347H/310S/904L), Duplex (2205/2507), Ferritic & Martensitic stainless families.

4. Continuous Casting

• Equipment: Tundish, mold, secondary cooling, segments, straightener, flying shear, on-line surface inspection/grinding; EMS & soft-reduction.

• QA/QC: Mold level, flux properties, spray curve; macro-etch (ASTM E381), UT per contract (ref. EN 10160 logic).

• Product mapping: Thin slab 50–110 mm, conventional 150–250 mm, extra-thick 450–600 mm; billet/bloom for bars/sections/forged-rolled.

5. Hot Rolling

5.1 Coils (HSM)

• Equipment: Reheating furnace, descaling, rougher/finisher, laminar cooling, coiler.

• QA/QC: Temperature & cooling curves, AGC/AFC, on-line surface.

• Products: HRC, pickled coils, hot strip; stainless hot coils/strip.

5.2 Plate Mill

• Equipment: Reheating, 4-high/duo reversing mill, ACC, leveller, UT.

• QA/QC: TMCP, thickness/flatness, lamellar tearing sensitivity.

5.3 Longs (Sections/Bars/Wire Rod)

• QA/QC: Geometry, controlled cooling, surface, coil density & scatter of tensile properties.

5.4 Pipes & Tubes

• Process: Seamless (piercing–rolling–sizing–HT–NDT–hydro/airtight) and welded (ERW/HFW, UOE/LSAW, SSAW/SAW).

• Dimensions: ASME B36.10/36.19, ISO 1127.

6. Cold Processing & Finishing

• Equipment: Pickling, 4/6/20-high cold mills, continuous/batch annealing, skin-pass, tension levelling, slitting & cut-to-length.

• Stainless: Pickling & passivation (ASTM A380/A967), BA bright anneal, EP electropolish.

• Tubes: Cold draw/pilger, stress relief, straightening; ID/OD surface class inspection.

• QA/QC: Dimensional tolerances (ISO 1127/EN 10305), laser measurement & SPC.

7. Surface Engineering & Corrosion Protection

• Pretreatment: Sa 2½ blasting; avoid free-iron contamination on stainless.

• Paint systems (ISO 12944): Zn-rich epoxy + high-solids epoxy + PU; multilayer or weatherable top for C5/CX.

• Metallic coatings: HDG (ISO 1461), thermal spray Zn/Al (ISO 2063), electro-zinc & phosphate/Dacromet.

• Pipeline: FBE (AWWA C213/CSA Z245.20), 3LPE/3LPP (ISO 21809-1); linings AWWA C205/C210/C222/C214/C215; rubber/PTFE/PFA/glass-flake by medium/temperature.

• Stainless surfaces: A380/A967 passivation, EP, ferroxyl test.

• Inspection: DFT, adhesion, impact/bend, holiday (AMPP/NACE SP0188), salt-spray & chemical resistance.

8. Quality & Certification (ITP)

• Chemistry: OES/ICP, C/S combustion, O/N/H fusion.

• Metallography & Corrosion: Inclusion rating, A923 (duplex), G48 pitting, A262 IGC.

• Mechanical: Tensile, CVN impact, hardness, creep & rupture (on demand).

• Geometry: Laser thickness/flatness, straightness/ovality/eccentricity for tubes.

• NDT: UT/RT/MT/PT/ET per standards & contract.

• Pressure & Tightness: Hydro/air/helium (clean/cryogenic).

• Docs & Traceability: EN 10204 3.1/3.2, heat-treat curves, NDT/pressure/coating QC, barcode/RFID end-to-end.

9. Digitalization & Process Control

• Level-1/2 models, MES, quality data lake & SPC; IR/thermal imaging, shape control, energy/vibration, PdM; KPI loop across raw-steel-cast-roll-finish-ship.

10. EHS

• Gas & hot-work interlocks, CO/CO₂/O₂ monitoring, thermal protection, LOTO; lifting & securing rules; dedusting, wastewater reuse, slag/fines recycling; TRT/CDQ; carbon management (BF-BOF vs EAF, CCUS/H₂ trends).

11. Logistics & Packing

• Forms: coils, plates, sections, bars/rod, straight/coil tubes.

• Packing: end caps, edge protectors, steel straps, anti-slip pads, VCI, wrap, wooden/steel pallets.

• Shipping: sea/rail/road; tropical moisture protection; full document set (packing/weight list, CoO, inspection).

12. Typical Standards Mapping (Examples)

• Stainless plates/coils: ASTM A240, EN 10088-2, GB/T 3280.

• Tubes: A312/A213/A269/A789; Ni-alloys B444/B423/B167/B622; sizes ASME B36.10/36.19 or ISO 1127.

• Structural/sections: ASTM A36/A572, EN 10025.

• Pipeline & OCTG: API 5L, API 5CT, NACE MR0175/ISO 15156.

• Water & coatings: AWWA C200/C205/C210/C213/C214/C215/C222; AMPP/NACE SP0188.

13. Sample “Tour-to-Delivery” Card

1. Slab incoming (MTC 3.1 with E381/UT) →

2. Hot rolling (AGC/AFC logs; on-line surface map) →

3. Pickling + cold rolling + anneal (heat/curve) →

4. Final inspection (chem/mech/dim/surface) →

5. Corrosion protection or passivation/BA/EP (DFT & holiday) →

6. Packing & ID (barcode/RFID) →

7. MTC 3.2 (if required) →

8. Shipment.

14. Tour Tips (Tech + Commercial)

• Tech: temp-chem-microstructure-defect loop; EMS+soft-reduction for center quality; stainless AOD/VOD & surface passivation.

• Commercial: standards & revisions, NDT coverage & rejection rules, traceability depth, coating/lining systems, packing & delivered quality, cross-family consolidation capability.

We Use Cookies

We use cookies and other tracking technologies to enhance your browsing experience, provide personalized content and targeted advertisements, analyze website traffic, and understand visitor behavior.

These include both first-party and third-party cookies. Some data collected through cookies may be stored on our servers to help us improve our website and services. Other cookies are managed by trusted third-party providers (such as Google Analytics), and the information they collect is stored on their platforms in accordance with their own privacy policies.

We Use Cookies

We use cookies and other tracking technologies to enhance your browsing experience, provide personalized content and targeted advertisements, analyze website traffic, and understand visitor behavior.

These include both first-party and third-party cookies. Some data collected through cookies may be stored on our servers to help us improve our website and services. Other cookies are managed by trusted third-party providers (such as Google Analytics), and the information they collect is stored on their platforms in accordance with their own privacy policies.

Essential cookies are required for core website functions, such as security, authentication, and payment. These cookies are always active and do not collect personally identifiable information.

These cookies help us understand how visitors interact with our website—for example, by tracking page visits and traffic sources—so we can improve site performance and user experience. Disabling them may limit our ability to analyze and enhance the services we provide.

These cookies enable enhanced features and personalization on our website, such as remembering your preferences or enabling third-party tools. They may be set by us or by trusted partners. If you choose to disable them, some features may not work as intended.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.